Engineering Portfolio

Professional Projects

Andersen Corporation - Manufacturing Engineering Internship

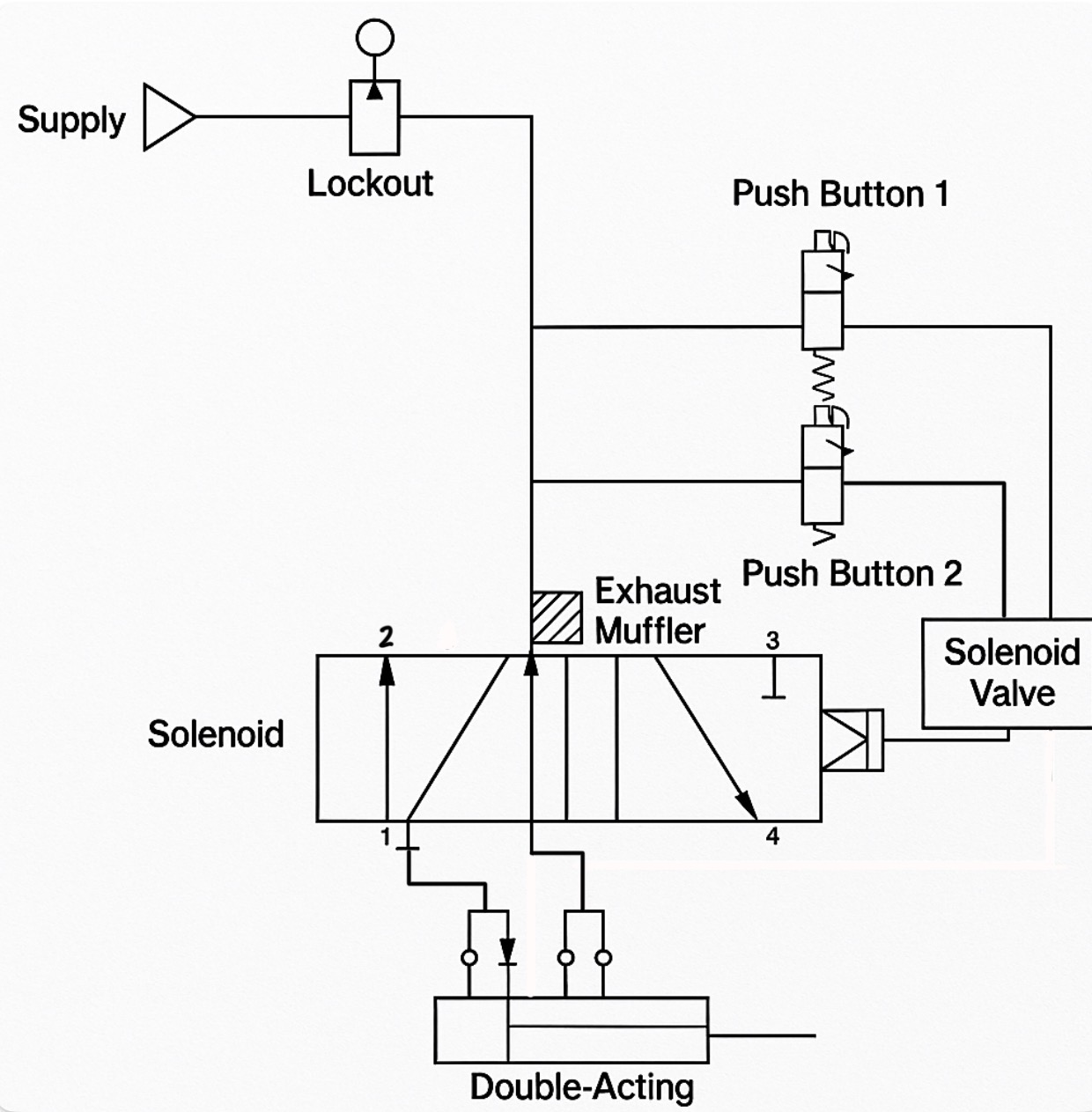

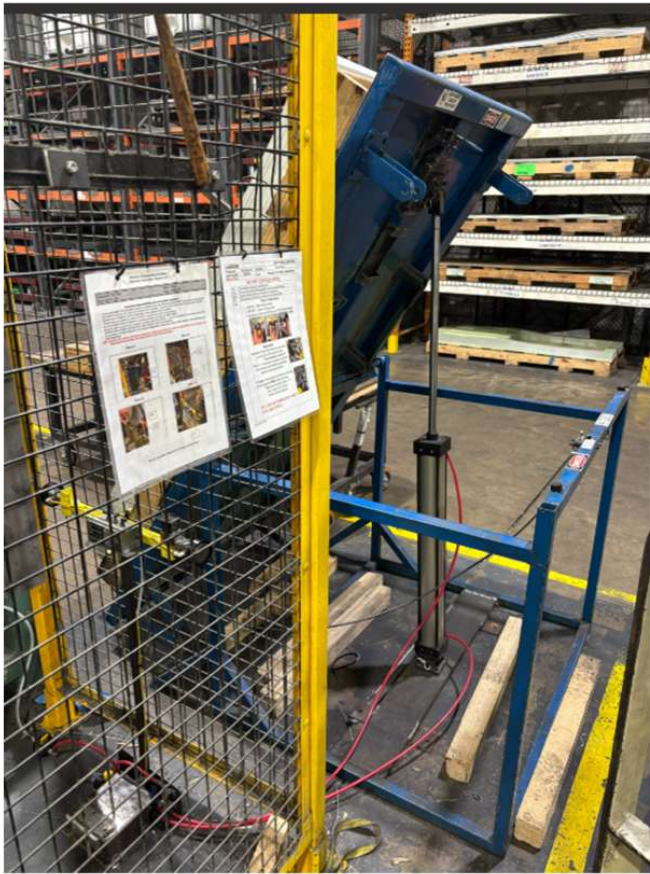

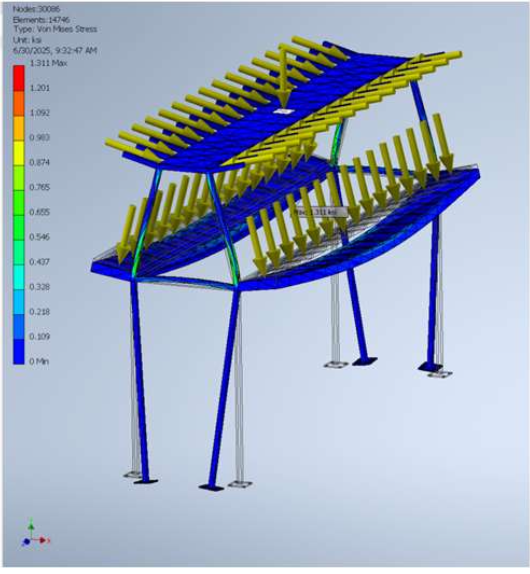

Pneumatic Tilt Table

Designed and fabricated a pneumatic tilt table to safely manipulate 1,000 lb panels across 500+ daily cycles. Created full CAD models in Autodesk Inventor, machined components in-house, and welded structural members. Integrated two hand pneumatic controls, mechanical safety interlocks, operator instructions, LOTO procedures, and ergonomic features to reduce operator fatigue while improving throughput and repeatability.

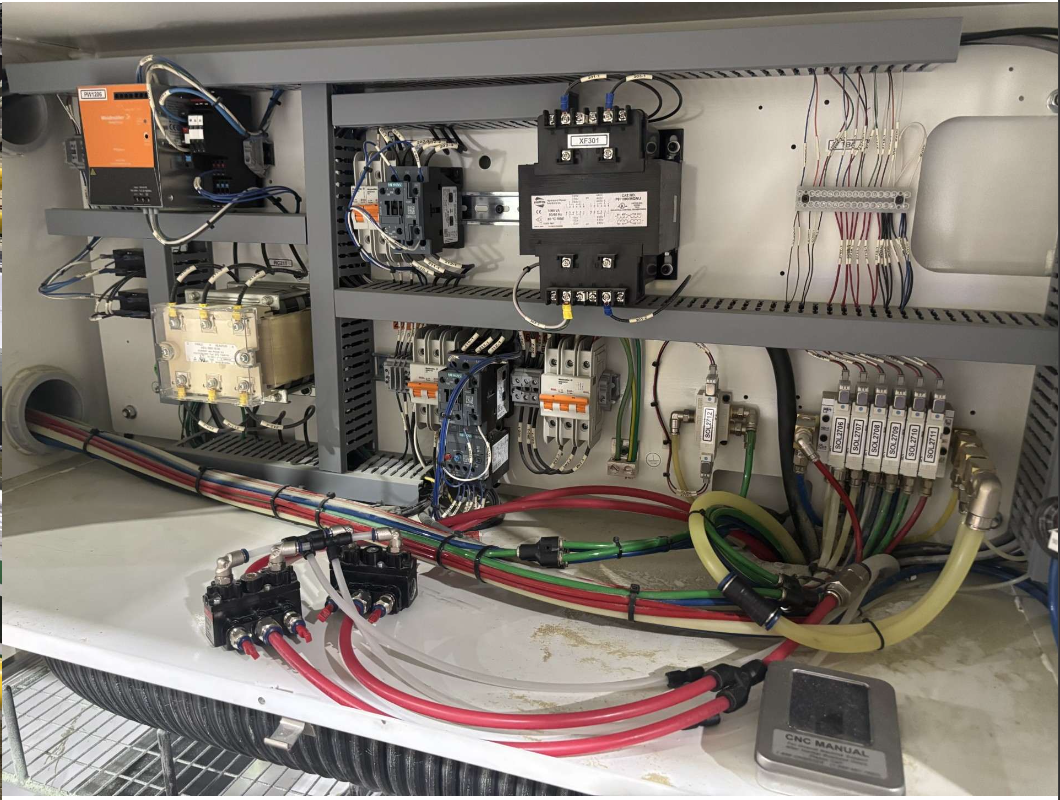

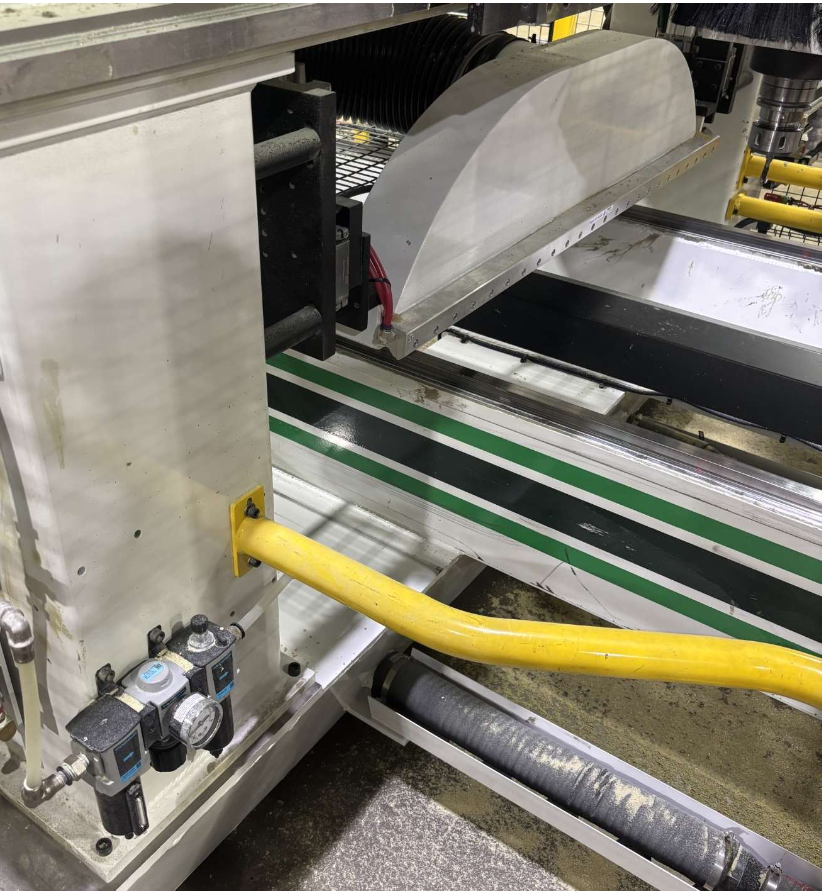

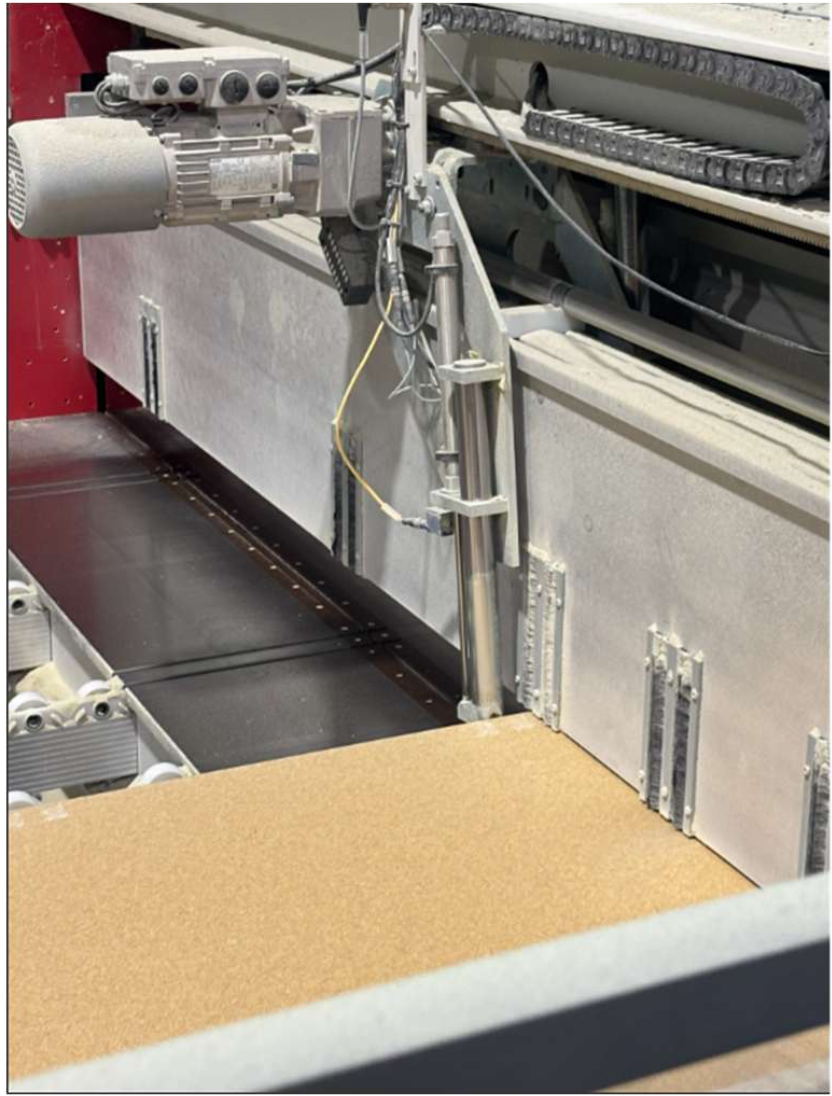

CNC Router Pneumatic Blow-Off System

Designed and installed a pneumatic blow-off system for a C.R. Onsrud CNC router to reduce debris accumulation during machining. Optimized airflow routing, regulator placement, and actuation logic to eliminate pressure loss, increasing output by over 20 doors per shift (~17%). The system improved cut quality, reduced surface defects, and minimized operator intervention.

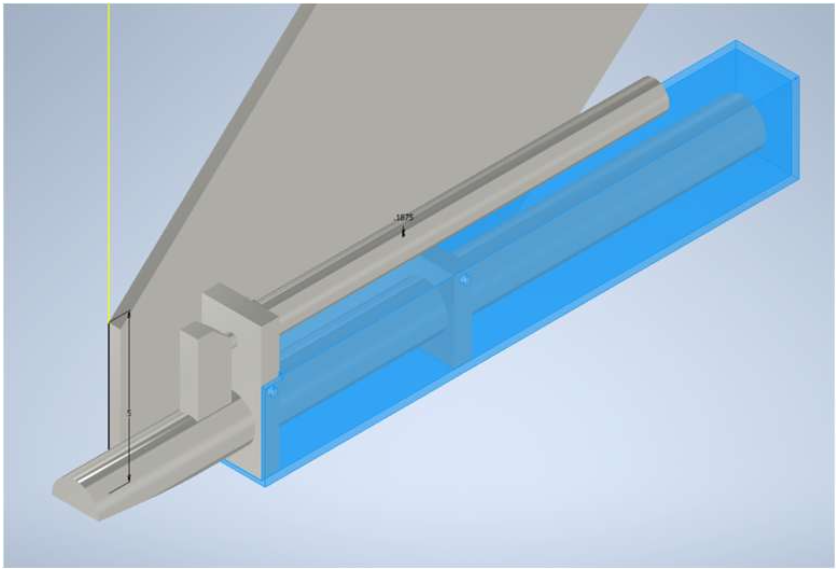

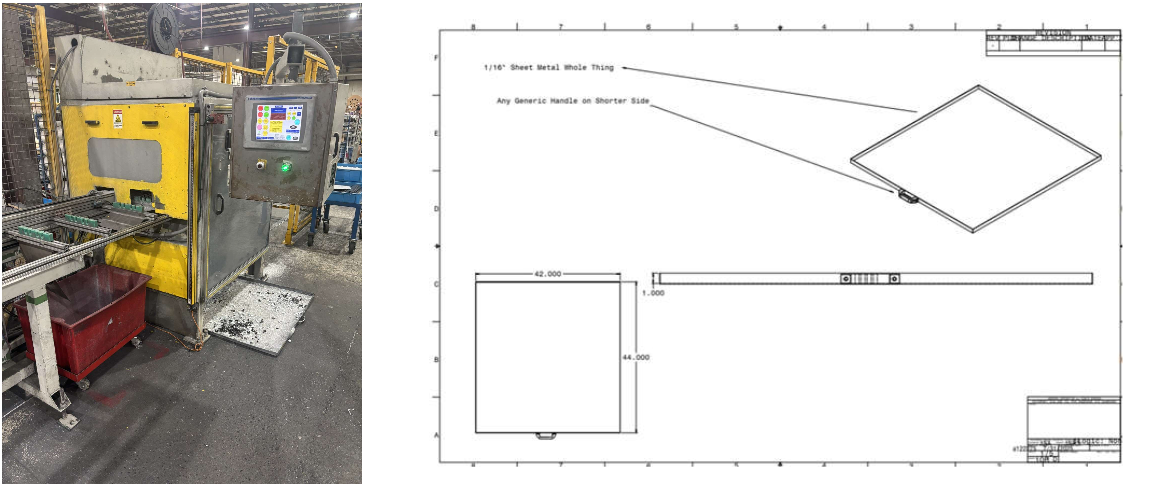

Chip Guarding System

Designed a precision-fit dust guarding system for a Schelling FH-6 beam saw using in field measurements and tight tolerance CAD modeling. Fabricated custom sheet-metal components to improve debris control, extend equipment life, and reduce maintenance costs by approximately $15,000 annually.

Glue Drip Guarding System

Designed and implemented a glue drip protection system to prevent adhesive buildup on equipment and surrounding components. Developed removable UHMW polyethylene guards and collection features that improved safety, reduced cleanup time, and minimized unplanned maintenance while maintaining operator accessibility.

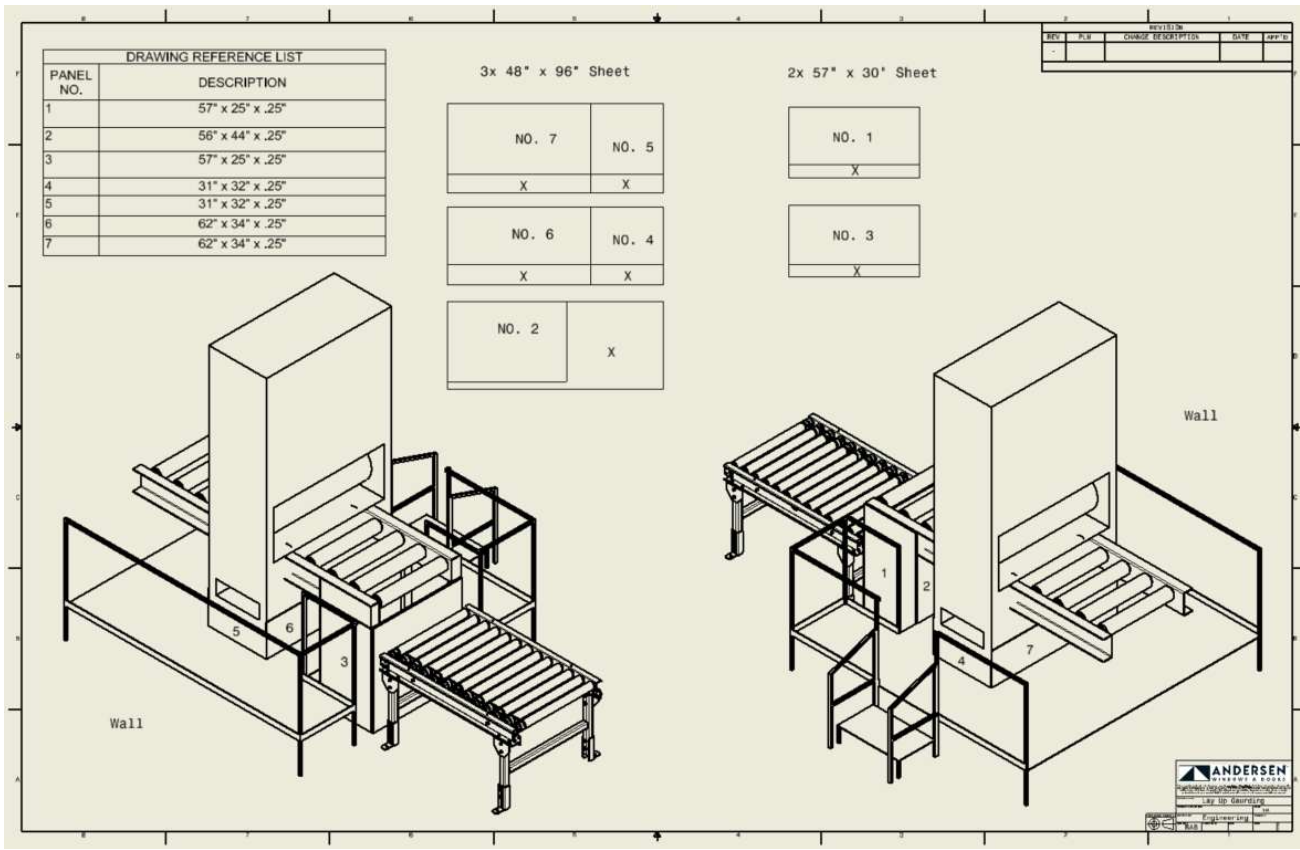

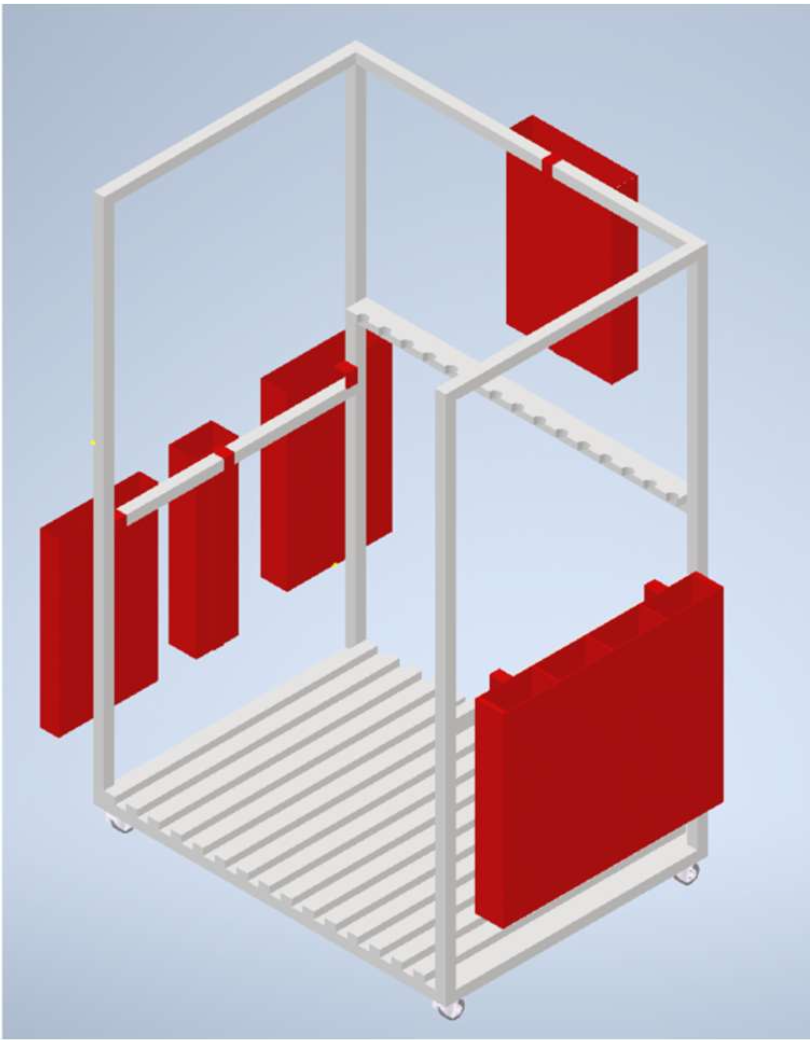

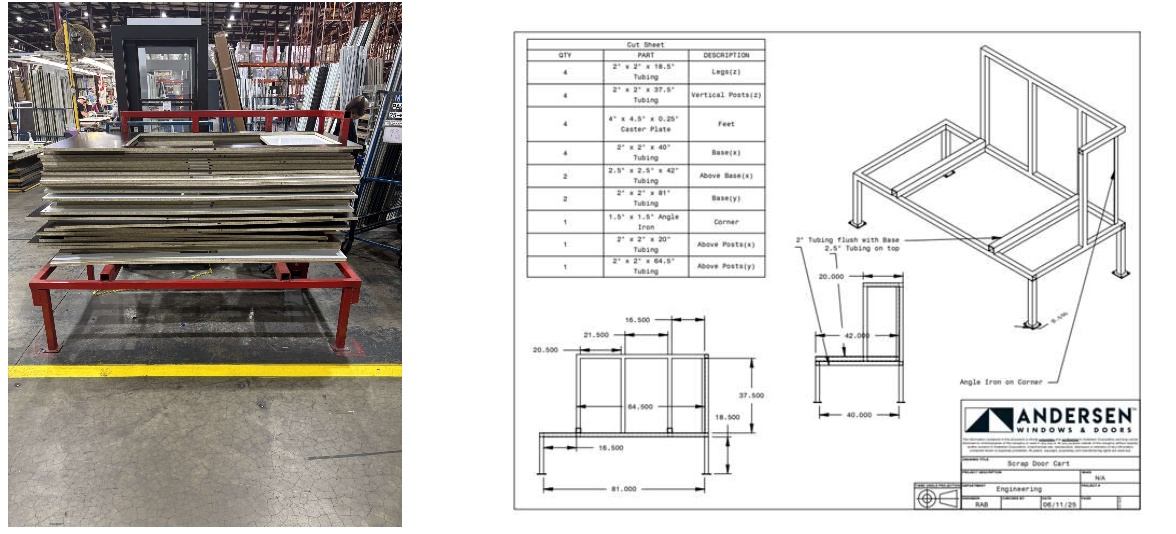

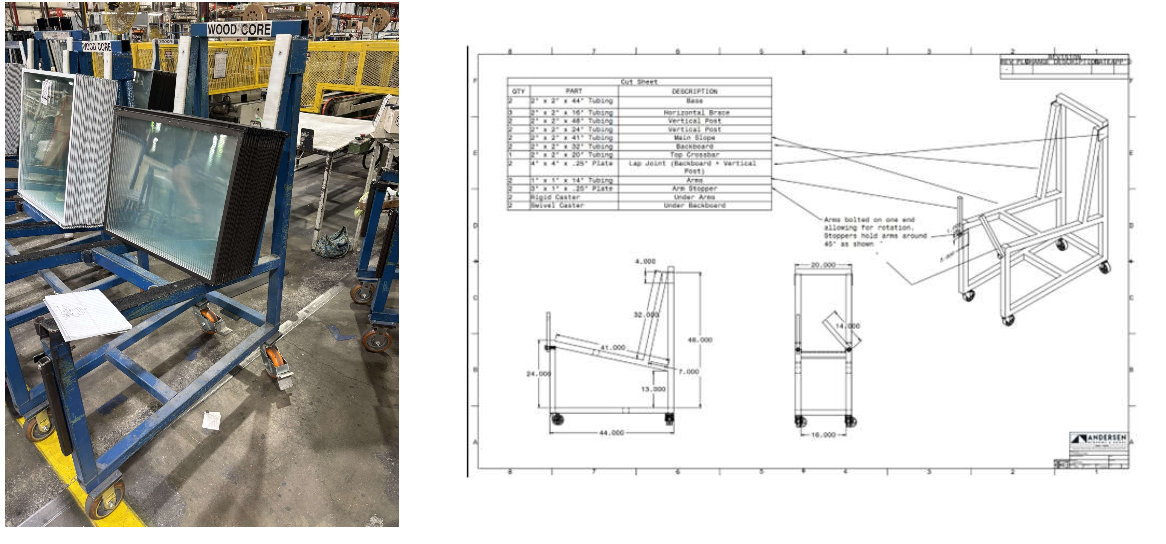

Modular Storage & Cart Systems

Developed multiple modular storage and transport solutions including vinyl scrap carts, door storage racks, and component handling fixtures. Led design from concept through fabrication, improving workflow efficiency, reducing material handling time, and enhancing shop-floor ergonomics.